Upgrades & Engineered solutions

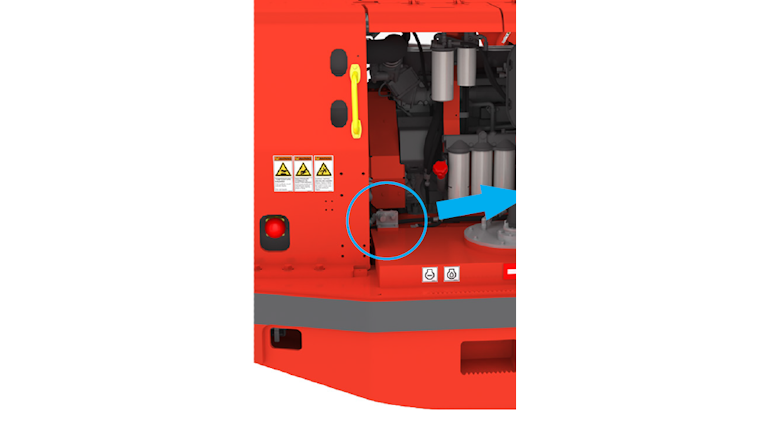

Return Filter Upgrade For Loaders

On it latest i-series loaders, Sandvik has introduced a new type of hydraulic return filter. This new filter brings several advantages:

-

Description

On it latest i-series loaders, Sandvik has introduced a new type of hydraulic return filter. This new filter brings several advantages:

• The filter is shorter and much lighter (-40% when wet) and it is offering firmer grip for lifting the element with a hook or with the fingers as there is more space on the top of the filter. Also, the bottom of the filter is flat making it stand alone when removed. This makes safer and easier the filter replacement. When less effort is needed, more concentration are possible for safe filter change-out. This is particularly true for this filter that has to be replaced form the top of the unit (risk of slip and fall from height).

• During the filter element installation, the magnet is guided with the help of a central rod. Magnet stays away from internal metal wire mesh and avoiding any touches with the filter media. So there is no more risks to damage the inside of the filter media or metal wire mesh during the installation process. Media surfaces stay clean and not defected. The possibility of having an element installed that won´t perform according to expectations leading to higher contamination of oil and premature wear of whole system components is then strongly mitigated. -

Advantages

• The new filter is shorter and lighter (-40% when wet). There is more space on the top to insert a lifting hook or the fingers.

• Smooth and ”cut free” surface of the filter element increasing handling safety. No welding beam.

• New filter element is a stand alone unit thanks to its plain bottom design (no falling down risk).

• Filter element can be installed carefully to the bottom plate without any magnet distractions. After the element installation, the magnet is guided by a central rod. Magnet stays away from internal metal wire mesh and avoiding any touches with the media.

• No special tools required to replace the filter element. No jigs or inserts.

• Same filter installed on latest Sandvik LH517i and LH621i.

Product specifications

- Application area

-

Safety and environmental improvement

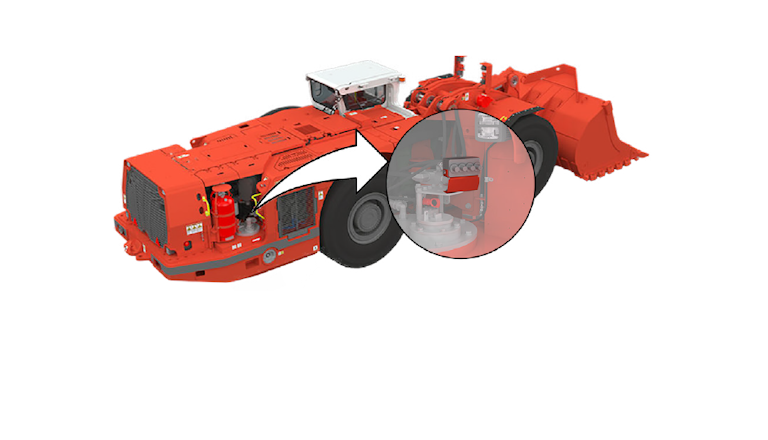

- Loaders

-

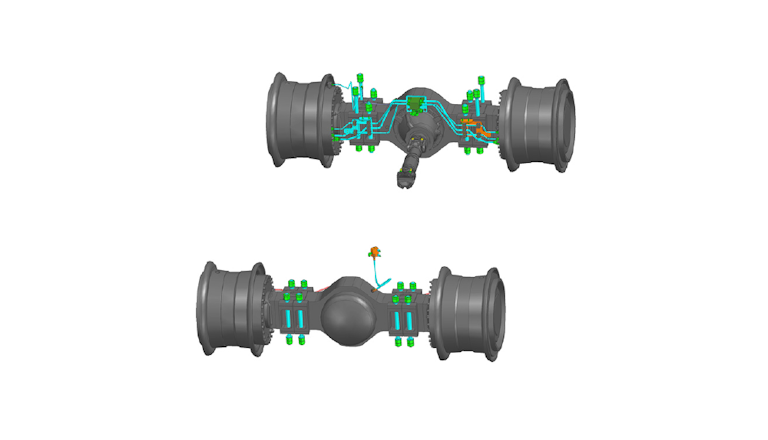

Sandvik LH621 / Sandvik LH517L / Sandvik LH517